|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LUGER WINDWARD BLUEPRINT DIAGRAMS

Circa 1973

A note from Agent Pat: All the diagrams you find here were copied from original Luger Assembly Plans (blueprints). The 24 x 36 inch documents were so old and faded that each diagram had to be redrawn and digitally enhanced before it could be scanned, to remove most of the discoloration for easier viewing.

This lengthy restoration project was undertaken by

Patrick "Agent Pat" Harrington

Pat began redrawing the blueprints because he is restoring a

1969 Luger Windward 20 Sloop

A note from Joanie and The Luger Sailboat Mooring: My involvement in this project started after Pat uploaded the Windward information onto his homepage website. I wanted to make the diagrams easier to view on the internet by enhancing them with color. In some cases I've re-written the text for clarification so the images could stand alone (without the step-by-step and part-by-part assembly directions).

I began augmenting* Pat's diagrams to complement the work he started,

and to make the information available on

The Luger Sailboat Mooring

www.lugerboats.com

You can e-mail "Agent Pat" with comments about his diagrams,

or his Windward restoration project at:

pharring@ksip.net

You can e-mail me with comments or questions

about this project's "Second Phase" at:

blueprints@lugerboats.com

* Each of the redrawn figures was "contrast enhanced" and "airbrushed" with color to make the images easier to view on a monitor. Most blueprint diagrams are self explanatory, and do not need the added "Assembly Instruction" text. It seemed easier to have a listing of the diagram "Figure Numbers", an explanation of what information each diagram depicted, and a list of the major Part Numbers.

Some of the more popular diagrams have been highlighted in BOLD text.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standing Rigging Diagrams

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagram Description

Rigging hardware placement

Placement of mast base and chainplates

Template for location of holes

Clew attachment with backer blocks

Stem Head Fitting

Cut 3/8" taper to the base of mast

Mast & Accessories Assembly

Jib Halyard Attachment

Boom End Assembly

Boom cleat attachment & sail slot cut-out

Downhaul cleat attachment

Cross section for downhaul cleat attachment

Spreader Bar Assembly

Mainsail outhaul and boom end assembly

Mainsheet Path

Mainsail halyard path at masthead

Upper and lower shroud attachment at hull

Jib & Forestay attachment to

Stem Head Fitting

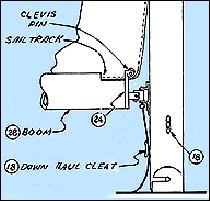

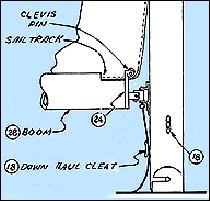

Boom, Gooseneck, Down Haul Assembly

Traveler Line Attachment

Mainsail to mast (parts and attachment)

Jib sail line attachment to jib

Jib Sail to Halyard Attachment

Rigging diagram - fore and aft views

Windward on Trailer - side view diagram

Rigging diagram - side view

Rigging Diagram - side view - close-ups

Masthead light installation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Major Rigging Part Numbers

Part 02 - Mast Head Casting

Part 04 - Mast Base

Part 05 - Nylon Sheave

Part 07 - Upper Shroud & Tang

Assemblies

Part 11 - Hound Assembly

Part 15 - Swing Spreader Bracket

Part 16 - Spreader Bar Tang

Assembly

Part 18 - Cleat

Part 24 - Gooseneck casting

Part 28 - Aluminum Boom Extrusion

Part 29 - Outhaul Casting

Part 30 - Tang

Part 31 - Becket Block

Part 32 - Single Swivel Block

Part 33 - SS Strap

Part 36 - Chain Plate

Part 35 - Channel Stay Adjuster

Part 42 - Stem Head Fitting

Part 43 - Cleat

Part 49 - Shackle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagram Description

Cable path from spool

Cable to Keel Attachment - assembly of parts

Cable to keel attachment - side view

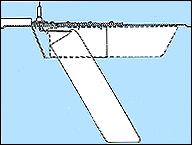

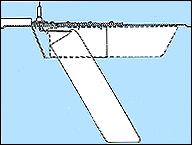

Insertion and attachment of keel within housing

Fiberglass bonding

Keel Housing

Keel and Winch Reinforcing

Apply Bonding Material to Housing area

Proper positioning of keel winch spool and frame

Keel Measurements

Centering Winch Cable on Spool

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Major Swing Keel Part Numbers

Part 1 - Pulley

Part 5 - Cable, Swing Keel

Part 12 - Swing Keel

Part 13 - Hinge, Swing Keel

Part 23 - Winch Spool

Part 300 - Hull, bottom

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General Assembly Diagrams

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagram Description

Attaching components with screws

Attaching components with screws

Repair damage to moulded fiberglass areas

Bonding parts using 2-layers of bonding material

Construction of Assembly Cradle

Preparation of Hull for Centerboard Well

Cross section of centerboard well attachment

Preparation for window installation

Window glazing and gasket installation

Fiberglass component assembly

Close-Up - Attaching hull sections

Attachment of transom

Proper attachment of fiberglass components

Proper attachment of bow components

Cross section of proper and improper installation

Three layer bonding of 6" wide material

Two layer bonding of 4" wide material

Two layer bonding of 4" material

Bow eye reinforcement

Bow eye and winch spool placement

Assembly of component parts

Reinforcement of fiberglass Part 304

Hatch Cut Out Reinforcement

Reinforcement of fiberglass Part 305

Close-Up of Part 305 Hatchway Reinforcement

Assembling & Bonding Parts 302, 304 and 305

Trimming part 305

Centerboard Well Assembly & Reinforcement

Centerboard assembly (Windward model)

Installation & Positioning of Centerboard

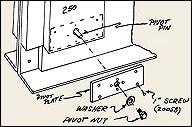

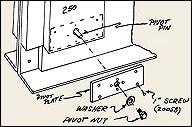

Cross section of well for pivot bolt positioning

Centerboard Well Cap Installation

Cross section of lower centerboard well section

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Major Assembly Part Numbers

Part 201 - Centerboard Cap

Part 212 - Mast Support (wood)

Part 300 - Hull, Bottom

Part 301 - Side Panel (fiberglass)

Part 302 - Side Panel (fiberglass)

Part 303 - Transom

Part 306 - Cabin Top (fiberglass)

Part 307 - Centerboard Well, Right

Part 308 - Centerboard Well, Left

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The "Harrington Project" was undertaken by Joanie Johnston. Pat "Agent Pat" Harrington had

redrawn blueprint diagrams, and Joanie Johnston later enhanced and altered diagrams

to make them easier to understand on a small format (computer monitor).

The enhanced drawings are an exclusive feature of The Luger Sailboat Mooring

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© 2006 j. rilling johnston all rights reserved

|

|

|

|

|

|